Our Services

Based on the outskirts of Norwich with a well-equipped workshop, we can fabricate our client’s design, or we can help with the design process through a technical partnership with a very experienced design house.

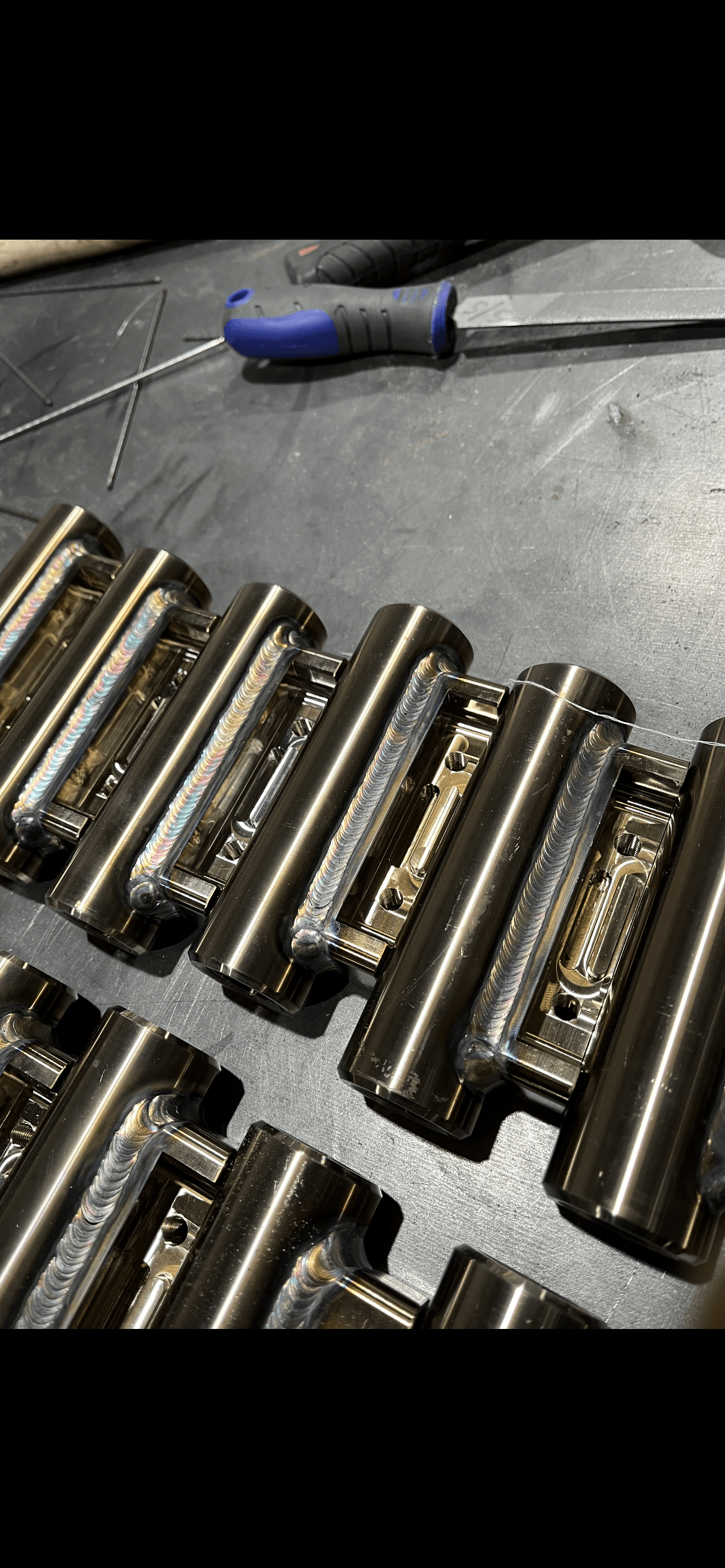

Pipe fabrication, carbon steel, stainless steel, and exotic metals

All pipe fitters, and fabricators will be time served, and hold relevant trade certifications, and all welders will be certified to weld to KPFS Ltd weld procedures. We currently have procedures for A333 (carbon steel), 316L ( stainless steel) , and 17-4PH (stainless steel) and Aluminium..

Coded welding to BS EN standards

Our weld procedures are certified to BS-EN 15614-1, and welder approvals to BS-EN 9606-1.

Workshop facility for offsite prefabrication.

Our fully equipped workshop on the outskirts of Norwich is our base for off site pre fabricated pipework, and structural steel. Equipped with 5 metre high roller shutter doors, we can cater for most fabrication needs. We own a good range of the most up to date welding equipment, and pipe fabrication tooling. With great links to all major routes we are happy to undertake projects nationwide.

Site installations of pipework and associated plant.

We have a dedicated site installation team, who are happy to work locally, and away when the workload dictates. We have worked on local installations including boiler houses, and plantrooms. Past experiences have been pipeline installations on COMAH sites, and more recently CHP and ASHP/GSHP installations nationwide, with all associated plant such as PHEX’s, large diameter exhaust systems, LTHW, HTHW, MTHW pipe systems, and Ammonia systems.

Client specific welding procedures.

We are in the process of adding further weld procedures to our capabilities, however we understand that clients may have specific requirements that may be a little more obscure. We are happy to arrange for procedure to be written via a qualified welding engineer, complete the practical element of the weld procedure within our facility, and take care of all NDT, and lab testing. We are happy to do this in any welding process, on any material, with any joint type, in any weld position.

Design through technical partnership.

Should you require a full turnkey mechanical design, fabrication, and installation, including testing, and commissioning, we can cater for your needs. Through a technical partnership with a very experienced design house, we can offer full design, laser scanning, 3D modelling, full equipment layout, detailed drawing, and project management. Please get in touch for a full breakdown of services we can offer.

Our Recent Projects

Since we began trading in June 2021, we have completed the de-carbonisation project of the Royal Berkshire Hospital in Reading, completed welding works for the new £26m Marina Centre in Great Yarmouth, all welding works for the plant room at the New University of Peterborough, and we have completed two new weld procedures for one of our valued customers. We have some exiting projects on the horizon for the remainder of 2022, but we are very much open to growth..